18. CNC CONNECTION

18.5 CNC Side Settings

18 - 21

17

ROBOT

CONTROLLER

CONNECTION

18

CNC CONNECTION

19

GOT MULTI-DROP

CONNECTION

20

MULTIPLE-GT14, GT12,

GT11, GT10

CONNECTION FUNCTION

21

MULTI-CHANNEL

FUNCTION

22

FA TRANSPARENT

FUNCTION

18.5.3 Ethernet connection

System configuration

The following shows the example of the system

configuration when using the CNC monitor function.

Parameter setting

Set parameters related to Ethernet with MELSEC’s

peripheral devices in the same way as parameter

setting of MELSEC CPU, and write them on CNC by

Personal computer.

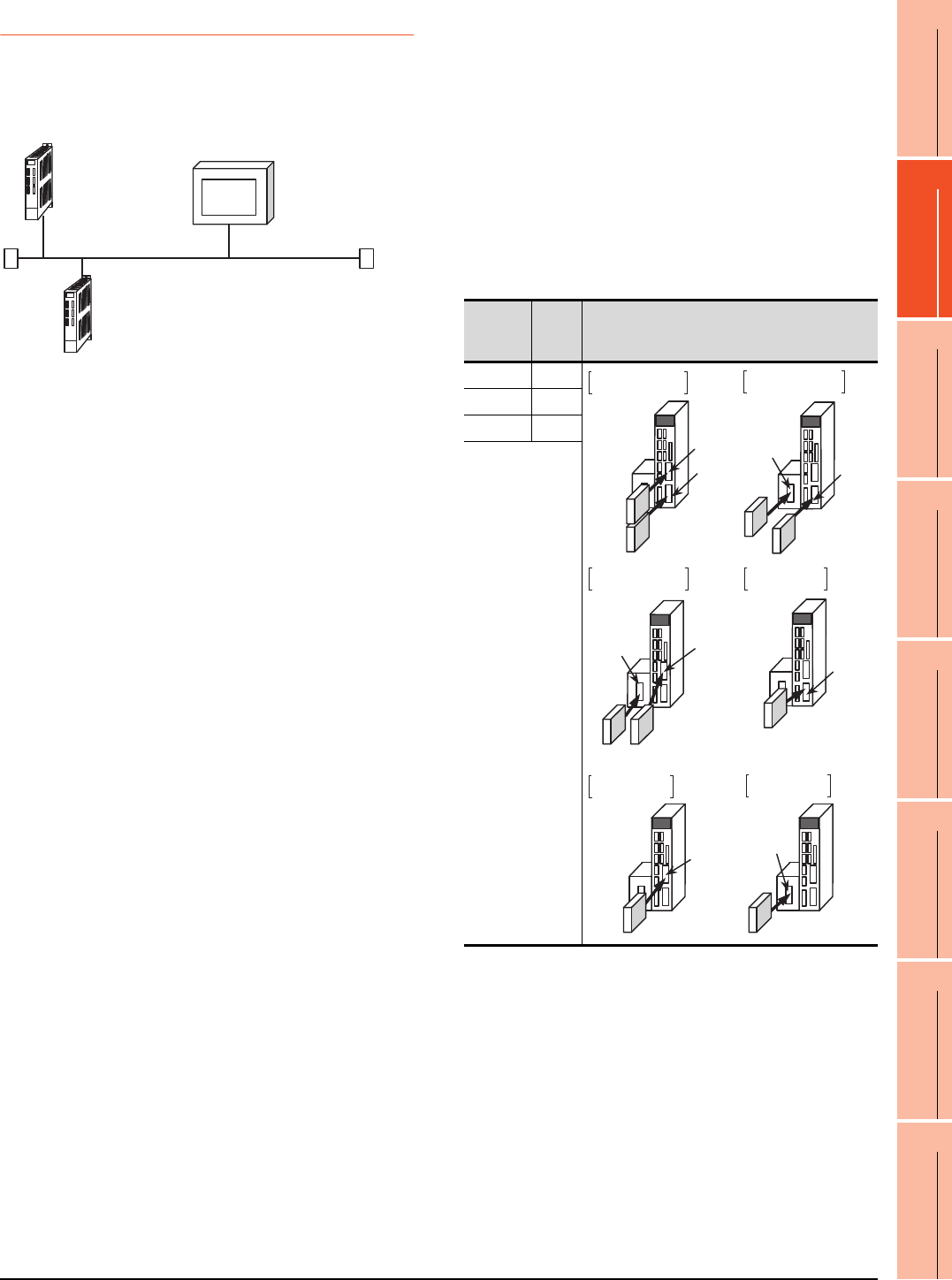

(1) Network parameter setting

Set the network parameters by peripheral device and

write them on CNC. An example of parameter setting

by GPPW is as follows. Set the first I/O No. as follows

according to the expansion slot to which the unit is

inserted.

(a) Unit No.

Ethernet (192.168.1.xx)

<CNC-1>

[Communication with GOT]

N/W No. :239

PLC No. :2

IP address :192.168.1.2

<CNC-2>

N/W No. :239

PLC No. :3

IP address :192.168.1.3

<GOT>

N/W No. :1

PLC No. :1

IP address :192.168.1.1

Slot

position

Start

I/O

No.

Mounting position of extension unit

EXT1 0200

EXT2 0280

EXT3 0300

EXT2

EXT1

Unit2

Unit1

EXT3

EXT1

EXT2

EXT3

EXT1

When mounted

in EXT2 only

When mounted

in EXT3 only

EXT2

EXT3

When mounted

in EXT1 and EXT2

When mounted

in EXT1 and EXT3

When mounted

in EXT2 and EXT3

When mounted

in EXT1 only

Unit2

Unit2 Unit1

Unit1

Unit1

Unit1

Unit1