8. ETHERNET CONNECTION

8.4 PLC Side Setting

8 - 43

1

PREPARATORY

PROCEDURES FOR

MONITORING

2

DEVICE RANGE

THAT CAN BE SET

3

ACCESS RANGE

FOR MONITORING

4

HOW TO MONITOR

REDUNTANT

SYSTEM

5

BUS CONNECTION

6

DIRECT

CONNECTION TO

CPU

7

COMPUTER LINK

CONNECTION

8

ETHERNET

CONNECTION

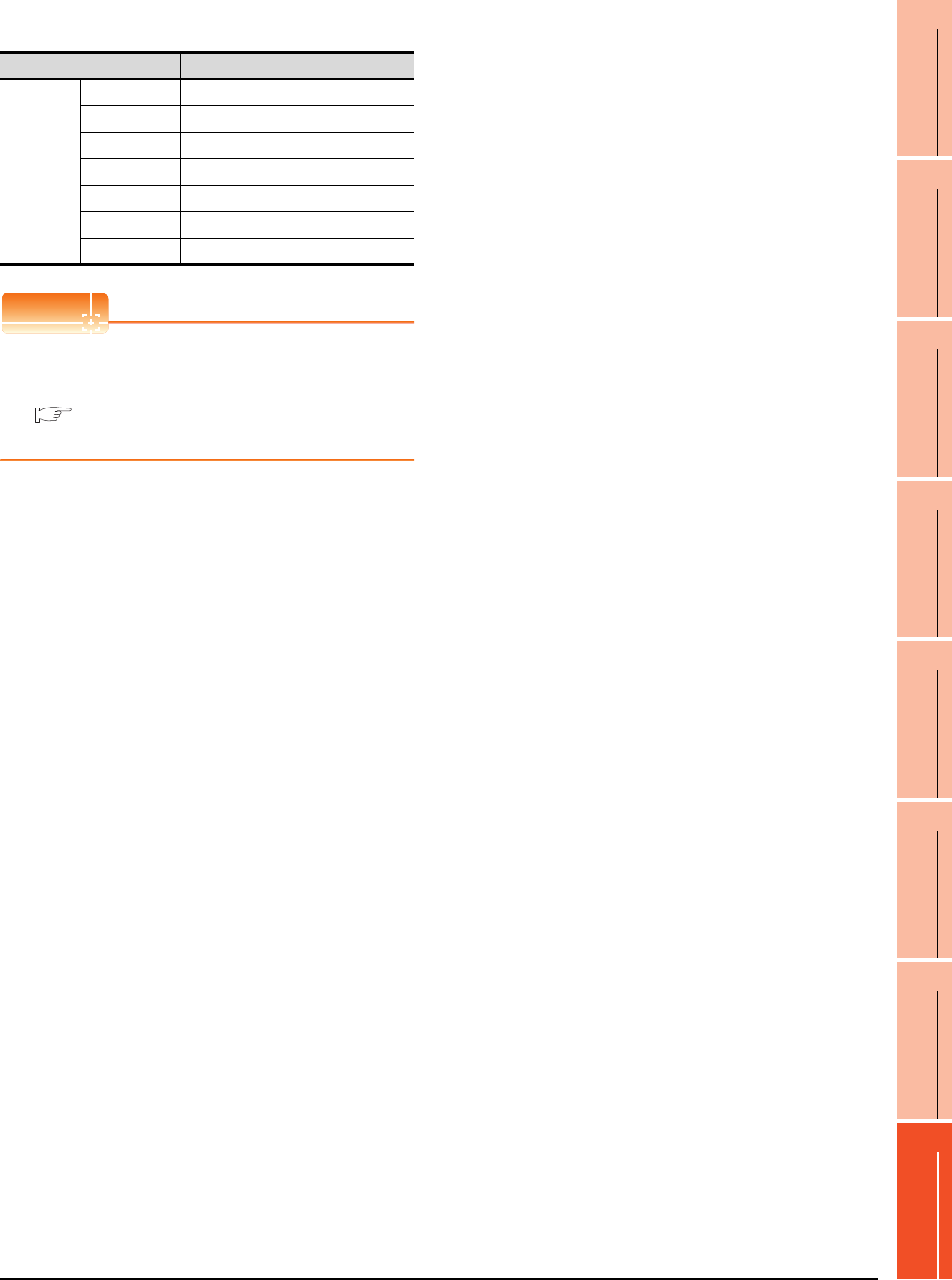

(2) Ethernet setting

POINTPOINTPOINT

[Controller Setting] and [Ethernet] of GT Designer3

For [Controller Setting] and [Ethernet] of GT

Designer3, refer to the following.

8.3.1 Setting communication interface

(Communication settings)

Checking communication state of CNC C70

(1) When using the Command Prompt of Windows

.

Execute a Ping command at the Command Prompt of

Windows

.

(a) When normal communication

C:\>Ping 192.168.0.19

Reply from 192.168.0.19: bytes=32 time<1ms

TTL=64

(b) When abnormal communication

C:\>Ping 192.168.0.19

Request timed out.

(2) When abnormal communication

At abnormal communication, check the followings and

execute the Ping command again.

• Mounting condition of CNC C70

• Cable connecting condition

• Switch settings and network parameter settings

• Operation state of PLC CPU (faulty or not)

• IP address of the CNC C70 specified for the Ping

command

Item Set value

Ethernet

setting No.1

Host *

N/W No. 1

PLC No. 2

Type Q17nNC

IP address 192.168.0.19

Port No. 5001 (fixed)

Communication UDP (fixed)