8. ETHERNET CONNECTION

8.4 PLC Side Setting

8 - 29

1

PREPARATORY

PROCEDURES FOR

MONITORING

2

DEVICE RANGE

THAT CAN BE SET

3

ACCESS RANGE

FOR MONITORING

4

HOW TO MONITOR

REDUNTANT

SYSTEM

5

BUS CONNECTION

6

DIRECT

CONNECTION TO

CPU

7

COMPUTER LINK

CONNECTION

8

ETHERNET

CONNECTION

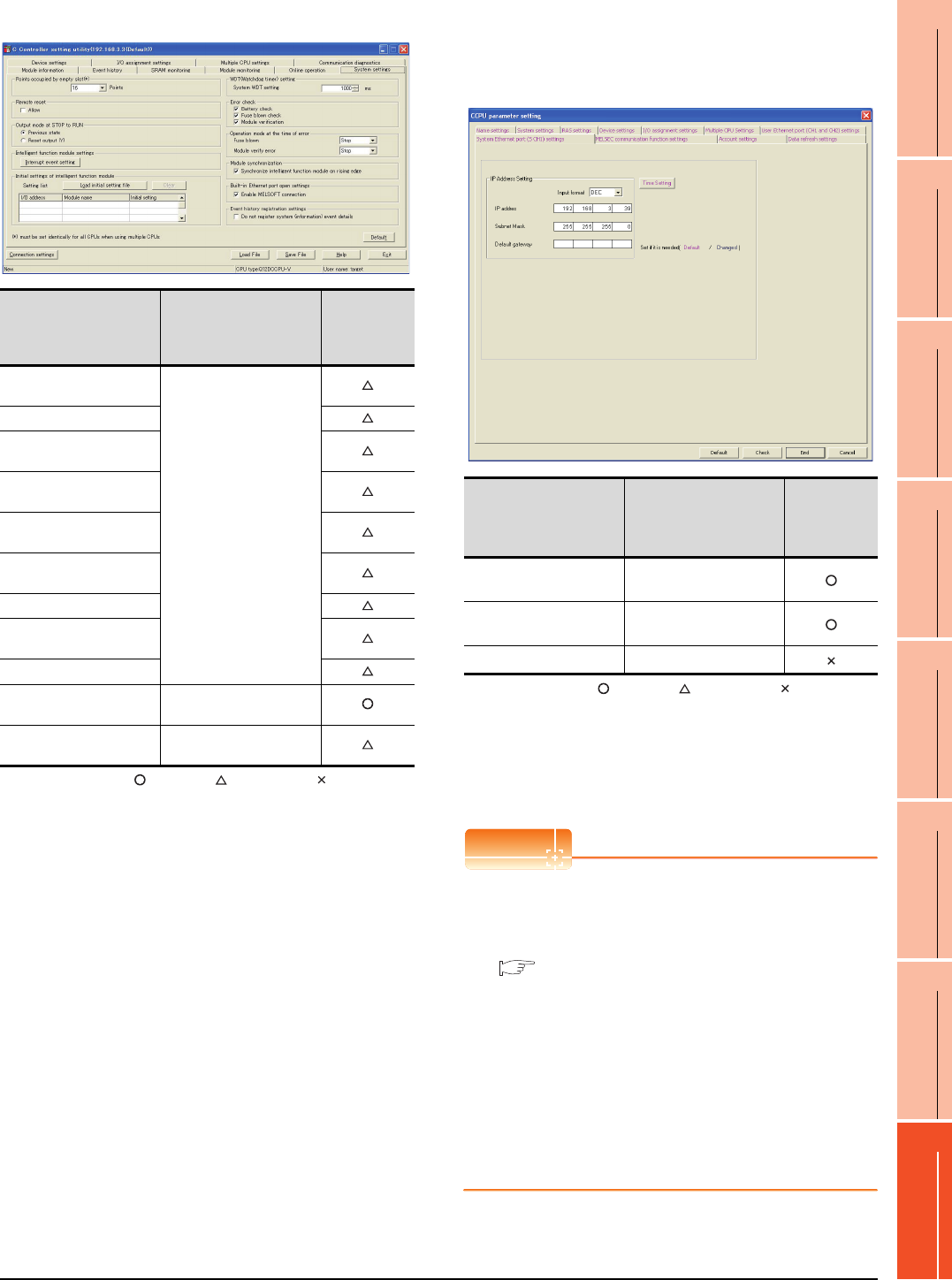

(d) System settings

: Necessary : As necessary : Not necessary

(2) Q24DHCCPU-V

Use SW4PVC-CCPU-E for the C Controller setting

utility.

(a) Connection settings

: Necessary : As necessary : Not necessary

*1 If the IP address of the C Controller module has been

changed, input the changed IP address.

[Controller Setting] and [Ethernet] of GT

Designer3

POINTPOINTPOINT

(1) [Controller Setting] and [Ethernet] of GT

Designer3

For [Controller Setting] and [Ethernet] of GT

Designer3, refer to the following.

8.3.1 Setting communication interface

(Communication settings)

(2) Ethernet setting

When connecting C Controller module to a GOT,

the setting items for the network No. and station

No. do not exist at the PLC side. However, these

virtual values must be set on the GOT side.

Therefore, set the network No. and station No.

Set the network No. that is not existed on the

network system and any station No..

Item Set value

Setting

necessity at

GOT

connection

Points occupied by empty

slot

(Use default value)

Remote reset

Output mode at STOP to

RUN

Intelligent function module

settings

Initial settings of intelligent

function module

WDT (Watchdog timer)

setting

Error check

Operation mode at the

time of error

Module synchronization

Built-in Ethernet port open

settings

Mark the checkbox

Event history registration

settings

(Use default value)

Item Set value

Setting

necessity at

GOT

connection

IP Address

*1

192.168.3.39

(Default)

Subnet Mask

255.255.255.0

(Default)

Default Gateway -