18. CNC CONNECTION

18.2 System Configuration

18 - 3

17

ROBOT

CONTROLLER

CONNECTION

18

CNC CONNECTION

19

GOT MULTI-DROP

CONNECTION

20

MULTIPLE-GT14, GT12,

GT11, GT10

CONNECTION FUNCTION

21

MULTI-CHANNEL

FUNCTION

22

FA TRANSPARENT

FUNCTION

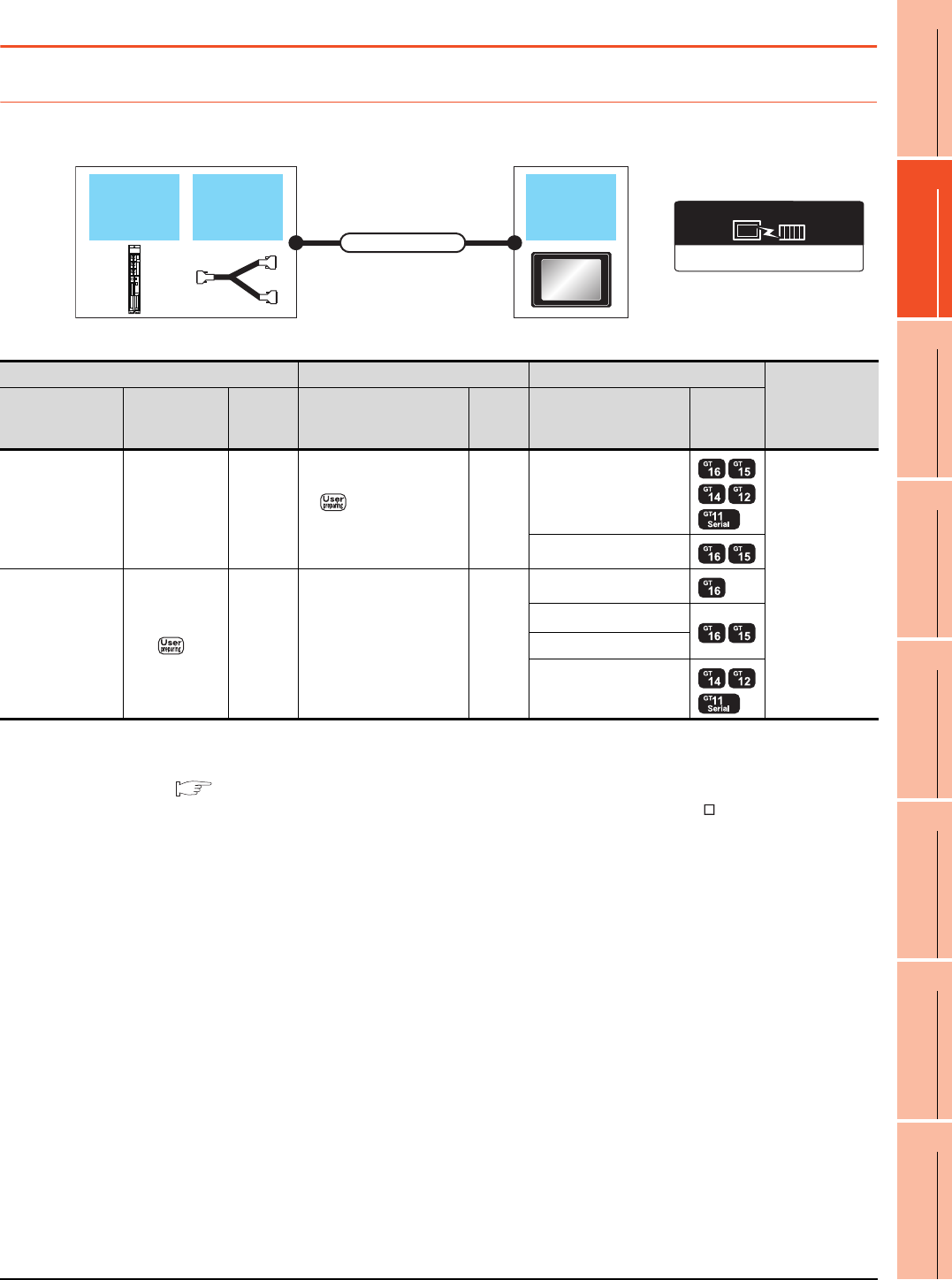

18.2 System Configuration

18.2.1 Direct connection to CPU

*1 Connect the connector of the CNC side to TERMINAL.

*2 Connect the connector of the CNC side to SIO.

*3 To be prepared by the user, referring the following.

MELDAS C6/C64 CONNECTION AND MAINTENANCE MANUAL (BNP-B2255) F311 Cable Production Drawing

*4 Connect it to the RS-232 interface (built into GOT). It cannot be mounted on GT1655 and GT155 .

AJ71C24, MELDAS C6*

Communication driver

F311 cable

GOT

Connection cable

MELDAS

C6/C64

CNC Connection cable GOT

Number of

connectable

equipment

Model name F311 cable

Communi

cation

type

Cable model

Max.

distance

Option device Model

MELDAS C6/C64

*1

- RS-232

RS232 connection

diagram

15m

- (Built into GOT)

1 GOT for 1 PLC

GT15-RS2-9P

MELDAS C6/C64

*2

*3

RS-422

GT01-C30R4-25P(3m)

GT01-C100R4-25P(10m)

GT01-C200R4-25P(20m)

GT01-C300R4-25P(30m)

30.5m

GT16-C02R4-9S(0.2m)

GT15-RS2T4-9P

*4

GT15-RS4-9S

- (Built into GOT)