7870 Interfacility Link Installation and User’s Guide page 27

Foxcom proprietary information

Appendix 1 Cleaning Fiber Optic Connections

Appendix 1.1 Cleaning Procedures for FC/APC Connectors ....................... 28

Appendix 1.2 Cleaning Procedure for FC/APC Bulkhead Ports................... 29

Appendix 1.2.1 Swab Method ........................................................................................... 29

Appendix 1.2.2 Compressed Air Method ......................................................................... 29

The unit has an FC/APC angle polished optical connector for very high optical return loss

performance. The units are specified into single mode fiber i.e. 9/125 micron core diameter.

Full performance is specified only for low return loss optical plant - meaning that the fiber

must be fusion spliced and all connections or splices must have a return loss greater than -60

dB. With these guidelines in mind, link lengths beyond 20 kilometers (DFB based products)

can be achieved with high performance. Specific performance and/or design assistance is

available by request from Foxcom.

If there is low/no signal or noisy signal at a Foxcom module, the connector should be cleaned.

Dirt on the inside connector tip can impair the flow of light causing problems in signal

transmission. Foxcom modules are sealed but dirt can occasionally enter during installation

and alignment.

The input and output optical ports of all Foxcom equipment are known in the fiber optic

world as bulkhead ports. Foxcom uses

FC/APC connectors.

The following materials are representative of the types of cleaning materials that should be

used for cleaning the fiber optic ports and connectors. They are available from several

suppliers.

Wiping clothes should be made of lint free alcohol free nonabrasive materials. Swabs should

have a tightly wrapped tip and be talcum- free. For removing dust from receptacles, a

canned compressed gas is recommended. Do not use commercial compressed air because of

risk of contamination.

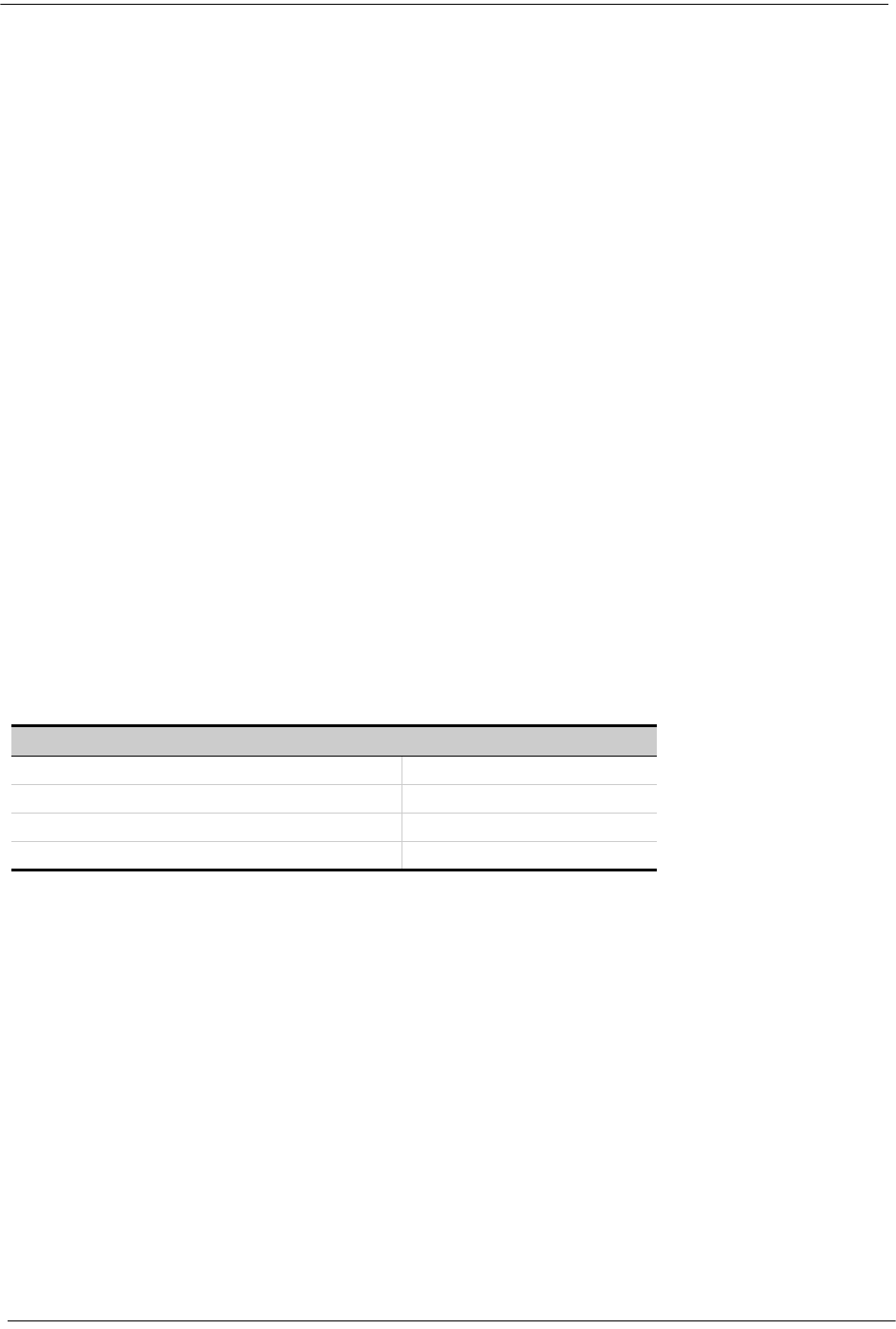

Description Manufacturer

Kim wipes Kimberly Clark

Cletop Automatic Connector Cleaner Cletop

fiber optic Swab Cletop or FIS

fiber optic Compressed Air Chemtronics

Table 10 Cleaning materials