Disassembly Instruction:

If necessary, the unit may be removed from the panel and

opened.

Warning: Disconnect all ac power from the unit

before proceeding.

1. Make sure the AC power is disconnected.

2. Remove all wiring connections from the rear of the

meter. To remove power and input connectors bend the

side panel detents on the case outward to release the

connectors, then pull connectors from the meter.

3. To remove meter from the case, squeeze left and right

sides of the bezel to release, then pull from case.

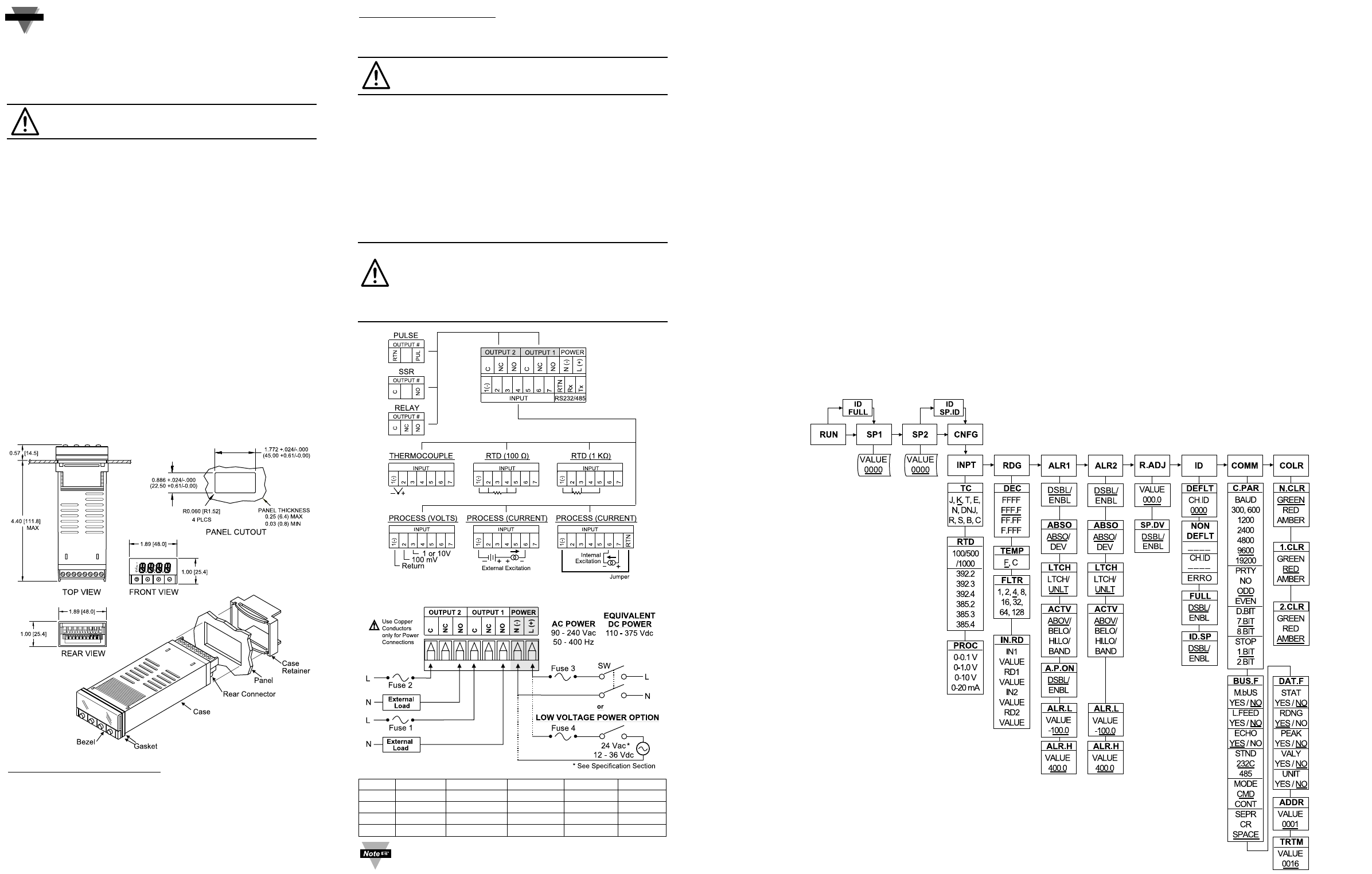

WIRING

Wire the instrument according to the figure shown below.

Warning: Do not connect ac power to your

device until you have completed all input and

output connections. This device must only be

installed by a specially trained electrician with

corresponding qualifications. Failure to follow

all instructions and warnings may result in injury!

Connect the main power connections as shown in the figure below.

FUSE Connector Output Type For 115Vac For 230Vac DC

FUSE 1 Output 1 Relay 3 A(T) 3 A(T) -

FUSE 2 Output 2 Relay 3 A(T) 3 A(T) -

FUSE 3 Power N/A 100 mA(T) 100 mA(T) 100 mA(T)

FUSE 4 Power N/A N/A N/A 400 mA(T)

Output 1 and 2 are for -AL Alarm Option only.

This Quick Start Reference provides information

on setting up your instrument for basic operation.

The latest complete Communication and Operational

Manual as well as free Software and ActiveX Controls

are available at www.omega.com/specs/iseries or on

the CD-ROM enclosed with your shipment.

SAFETY CONSIDERATION

This device is marked with the international

Caution symbol.

The instrument is a panel mount device protected in

accordance with Class II of EN61010-1. Remember that the

unit has no power-on switch. Building installation should

include a switch or circuit-breaker that must be compliant to

IEC 947-1 and 947-3.

SAFETY:

• Do not exceed voltage rating on the label located on

the top of the instrument housing.

• Always disconnect power before changing signal and

power connections.

• Do not use this instrument on a work bench without

its case for safety reasons.

• Do not operate this instrument in flammable or

explosive atmospheres.

• Do not expose this instrument to rain or moisture.

EMC:

• Whenever EMC is an issue, always use shielded cables.

• Never run signal and power wires in the same conduit.

• Use signal wire connections with twisted-pair cables.

• Install Ferrite Bead(s) on signal wire close to the

instrument if EMC problems persist.

MOUNTING

Panel Mounting Instruction:

1. Using the dimensions from the panel cutout diagram

shown above, cut an opening in the panel.

2. Insert the unit into the opening from the front of the

panel, so the gasket seals between the bezel and the

front of the panel.

3. Slide the retainer over the rear of the case and tighten

against the backside of the mounting panel.

START HERE

FLOW CHART

CONFIGURATION

MENU Mode:

Flashing display in MENU Mode means you can make your

selection by pressing

b

button. If the flashing display is not

a four digit value, pressing

c

button will always direct the

instrument one step backward of the top menu item. The

second push on the

c

button will reset the instrument

except after the setpoint and the alarms, that will go to the

RUN Mode without resetting the instrument. The

a

button

will always sequence the instrument thru the menu items.

The

d

button has two functions:

1. To save a selected flashing display

2. To direct the instrument to the next submenu level

RUN Mode:

b

causes the display to flash the PEAK with the

corresponding value. Press again to go back to RUN

Mode.

c

causes the display to flash VALLEY with the

corresponding value. Press again to go back to RUN

Mode.

d

causes flashing PEAK or VALLEY to reset corresponding

values. Press

d

one more time to go back to RUN Mode.

_____ Underline denotes factory default setup

OPERATION - (For Thermocouple Input)

Step 1. Apply Power to the Instrument

When your device is first powered up it will display the

ambient temperature (assume 75°F).

Step 2. Enter Setpoint 1 Menu

Press

a

one time from run mode to get to

SP1

Setpoint 1.

Step 3. Enter the Setpoint 1 Value Submenu

Press

d

. Display shows the previous selection of Setpoint 1.

Step 4. Change the Setpoint 1 Value

Press

b

or

c

until desired value is displayed.

Step 5. Store the Setpoint 1 Value

Set the Setpoint 1 to 10 degree higher than Process value

(SP1 = 85) and press

d

to store, display flashes

STRD

message and advances to

SP2

Setpoint 2 Menu.

Step 6. Store the Setpoint 2 Value

Repeat steps 3 and 4. Set the Setpoint 2 to 5 degree higher

than Process value (SP2 = 80) and press

d

to store,

display flashes

STRD

message and advances to

CNFG

Configuration Menu.

Step 7. Enter the Input Type Menu

Press

d

to enter

INPT

Input Type Menu.

Step 8. Enter to the submenu items of Input Menu

Press

d

to display Input: Process, RTD or Thermocouple.

If flashing

T.ç

is displayed press

a

and proceed to Step 11.

Step 9. Scroll through available selection of Input Menu

Press

b

until a flashing

T.ç

for Thermocouple is displayed.