Subwoofers

SW9100 Titanium DVC Pro Series

SW9100 Titanium DVC Series

40

The SW9100 Titanium Double Voice Coil (DVC)

series subwoofers were developed to meet the

need for subwoofers that combine quick

response, efficiency and very high SPL

performance. These demanding specifications

required the development of the radical new

technologies used in engineering and building

the Titanium series subwoofers.

Performance that's a revelation

Apart from delivering prodigious amounts of

low frequencies, truly excellent subwoofers

show what they’re made of by the quality of the

low frequencies they produce. Along with

moving lots of air, the ability to define the pitch

of the low notes is important and to preserve

transients is crucial. To do that, subwoofer

cones have to be able accelerate fast. The ability

of the low-mass high X-max 15˝ to move faster

than a typical 8˝ woofer but provide bass like an

18˝ cone is what make the SW9100 Titanium

DVC Series deliver such exceptional

performance.

Solid titanium cone

The solid titanium cone adds the best of this

metal’s properties to the subwoofer: very high

tensile strength, high stiffness to mass ratio,

excellent heat dispersion and corrosion

resistance. At high power levels, the titanium

cone resists the cone flex that causes coloration

and distortion, moving air efficiently throughout

the full power handling range.

2-inch surround

The surrounds are two inches wide to

accommodate speaker travel of 3.5 inches peak

to peak excursion. Made of special polyether

foam that is resistant to ultraviolet radiation and

moisture, the surrounds have superior

mechanical properties and the low mass needed

to produce extremely high excursions.

Aluminum voice coil

The voice coil former is made of 8/1000˝ thick

aluminum, much thicker than industry standard,

to handle the stresses of the high power motor

at large displacements. The voice coil wire is a

high-temperature aluminum wire, used to

minimize mass and maximize thermal radiation.

Since the bond between cone and former is

thermally conductive, the voice coil heat is

quickly dissipated throughout the entire

titanium cone. The superior conductivity

combined with unparalleled heat dissipation of

this voice coil and former assembly means

more power transfer into the cone movement

instead of wasted heat.

Dual symmetrically arranged spiders

Two spiders designed with special non-linear

Finite Element Analysis (FEA) software are

spaced precisely apart to keep the voice coil

centered in the motor structure. The woven-in

tinsel lead wires are the ultimate in durability

and power transfer. The synthetic fabric used to

manufacture the spiders is four times stronger

than conventional material used in most

subwoofers.

High force motor structure

The motor structure was designed to maximize

the force versus displacement curve of high

excursion drivers. The motor has a unique

shape that results in 20% more force from the

same magnets than is normally achieved. The

magnetic field is very symmetrical above and

below the magnetic gap, contributing to a low

distortion and audibly superior driver.

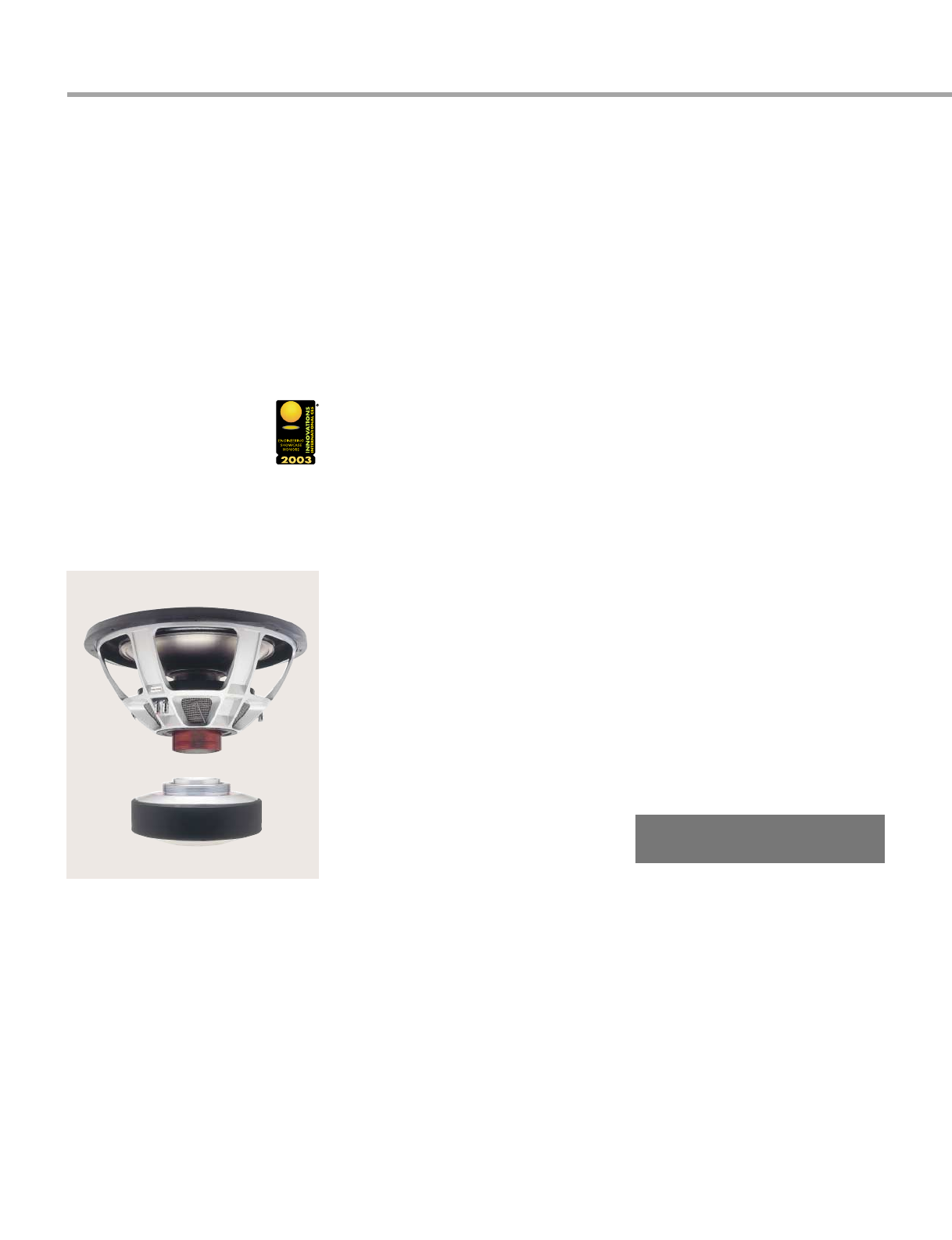

QCA (Quick Change Assembly)

technology

ECLIPSE QCA exclusive technology has

designed the speaker to instantly allow

its two sections to separate in the event that the

speaker cone gets physically damaged. Simply

unlock the two sections with one allen key, twist

off the speaker assembly (QCA) and replace

with another.

Cast aluminum frame

The aluminum frame forms the skeleton of the

high performance Titanium series subwoofers.

Venting below the spiders accommodates the

enormous amounts of air that are moved during

operation, as well as keeping the motor

assembly free of any excess heat. The cast

frame also acts as a heatsink to dissipate any

additional heat produced from the subwoofers.

Triple-stacked magnet

ECLIPSE Titanium subwoofers feature a

extra-long magnet and pole piece to accurately

control woofer travel and enable high-power

performance.

One-piece machined back plate and

pole piece

The back plate and pole pieces of a Titanium

series subwoofer are machined from a single

block of low-carbon steel. This expensive

process yields a component part of unparalleled

precision and results in a highly efficient

magnetic circuit.

Aero-vented pole

The pole piece of the subwoofer is aero-vented

both outside and inside to facilitate the laminar

flow of air into and out of the voice coil area for

superior motor cooling. Aero-venting also

reduces vent noise in high driver travel

conditions.

The Advantage of

Dual Voice Coil (DVC)

Dual Voice Coil speakers are designed to

maximize space for more flexibility during

installation. A dual-voice coil speaker is

essentially two speakers in one: two separate

voice coils are connected to the amplifier.

Depending on the impedance of each voice coil,

the two can be combined in a parallel or series

configuration to match the impedance ability of

the amplifier. The dual voice coil design does

not sacrifice system power handling or SPLs.

Replaceable section

Retained section